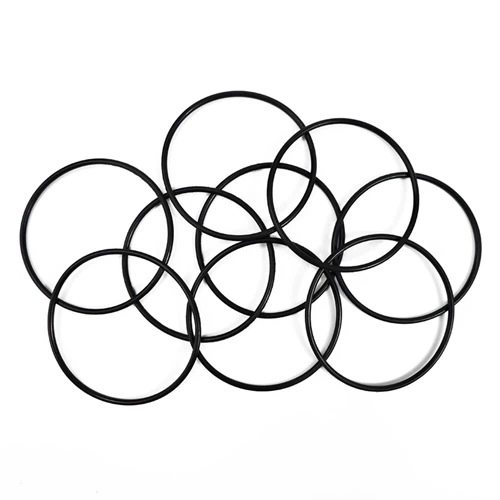

X-ray machine probe seals: a protective barrier for critical components

As an important equipment widely used in medical diagnosis, industrial testing, and safety inspection, one of the core components of an X-ray machine is the probe. The performance of the probe has a direct impact on the imaging quality and detection accuracy of the X-ray machine. The importance of the probe seal, as a key component to protect the probe from the external environment, is self-evident. This article will detail the role of X-ray probe seals, design requirements, and common types.

The role of seals

Prevent contamination: Seals keep dust, moisture, and other fine particles inside the probe and keep the internal environment clean to avoid damage to sensitive components such as detectors.

Detector protection: X-ray detectors are usually very sensitive to environmental changes, and seals can protect the detector from changes in temperature and humidity, ensuring its stability and reliability.

Extended equipment life: Good sealing performance can reduce the wear and aging of the probe's internal components, thereby extending the X-ray machine's overall life.

Improved safety: In medical and industrial applications, it is critical to prevent X-ray leakage, and seals ensure that the probe is tightly sealed to avoid potential hazards to operators and the environment.

| Product name | X-ray machine probe seals |

| Product material | Rubber, metal, silicone, fluoroelastomer |

| Hardness (Shore A) | 60 to 90 Shore A |

| Applicable temperature °C | Normal temperatures |

| Color | Black, orange, blue, yellow, green, custom |

| Size | Standard/ Custom |

| Advantage | High-temperature resistance, wear resistance, corrosion resistance |

| Application | X-ray machine |

| Certification | ISO: 9001, ISO: 14001, IATF: 16949 |

Design requirements

High sealing performance: Seals must be able to provide long-term stable sealing, even in harsh operating environments.

Material compatibility: The sealing material must be compatible with other X-ray machine parts without causing chemical reactions or physical damage.

Radiation resistance: In medical X-ray machines, seals need to be able to withstand X-ray radiation without degradation or degradation.

Ease of Maintenance: Seals should be designed with ease of replacement and maintenance in mind to reduce maintenance time and costs.

Common types

Rubber seals: Rubber seals are the most common type of seals, they have good elasticity and sealing properties and are easy to install and replace.

Metal seals: Metal seals are typically used where they need to withstand higher pressures or temperatures, and they have excellent wear and heat resistance.

Silicone rubber seals: Silicone rubber has good radiation resistance and high-temperature resistance, and is suitable for medical X-ray machines and other equipment with high requirements for sealing performance.

Fluoroelastomer seals: Fluoroelastomers have excellent chemical and oil resistance, making them suitable for X-ray inspection equipment in the chemical and petroleum industries.

Maintenance of seals

Regular inspection: Regularly check the wear and tear of the seal and the sealing effect, and find and replace the damaged seal in time.

Cleaning and maintenance: Clean the surface of the seal regularly to remove the attached dust and dirt to maintain good sealing performance.

Environmental control: control the temperature and humidity of the working environment of the X-ray machine to reduce the adverse effects on the seals.

Proper installation: When replacing seals, ensure that the correct methods and procedures are followed to avoid seal failures caused by improper installation.

Conclusion

X-ray machine probe seals are a critical component in ensuring the performance and safety of your equipment. With the continuous expansion of the application field of X-ray machines, the performance requirements for seals are also increasing. Both manufacturers and users need to pay attention to the selection and maintenance of seals to ensure the efficient, stable, and safe operation of X-ray machines. By employing high-performance sealing materials, reasonable design, and standardized maintenance, the service life of the X-ray machine can be effectively extended, and its reliability and accuracy can be improved in various applications.

Hot Tags: x-ray machine probe seals, China x-ray machine probe seals manufacturers, suppliers, factory, Medical Rubber Piston, Faucet Sealing Rings, Air Water O Ring For Syringe, Aerospace HNBR Rubber Seals, Centering Rings, O Rings Seals